- 08086813337, 08035749550

- info@d9thenterprises.com

At D9th enterprises, our foundry casting is a critical manufacturing process that we use in transforming raw materials into various metal components through a series of carefully orchestrated steps. This process is essential in producing equipment used across multiple sectors, including construction, mining, and manufacturing. our foundry casting undergo a well detailed process for specific equipment production, this includes channel gratings, manhole covers, hammers for impact crushers, jaw plates, couplings, counterweights, and liners.

Our foundry process generally involves several key stages:

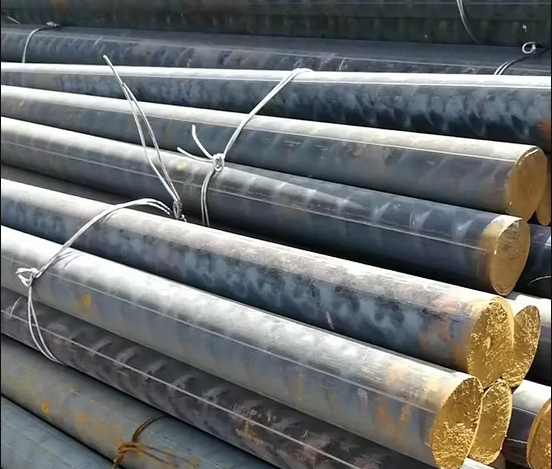

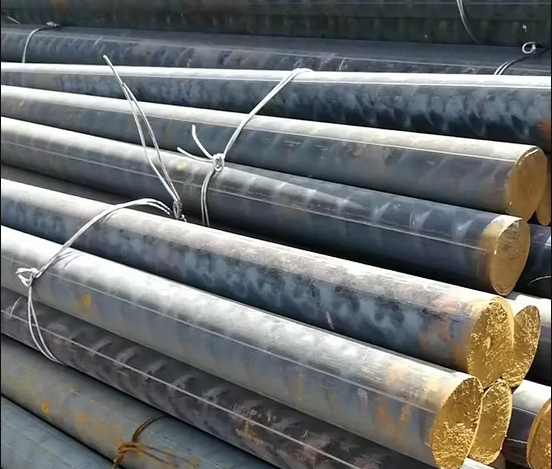

Melting: Raw materials such as scrap iron and pig iron are melted in a furnace at high temperatures to create molten metal.

Degassing: This step removes impurities and gases from the molten metal to enhance the quality of the final product.

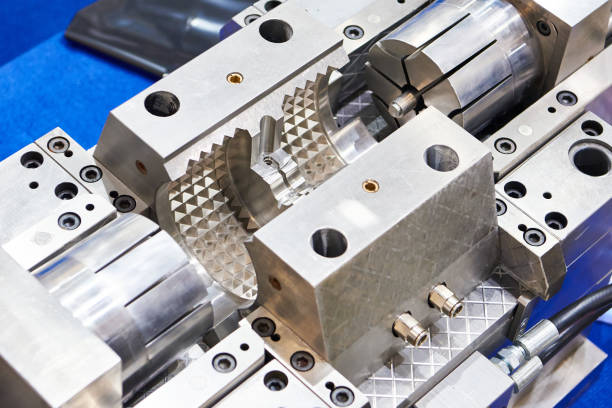

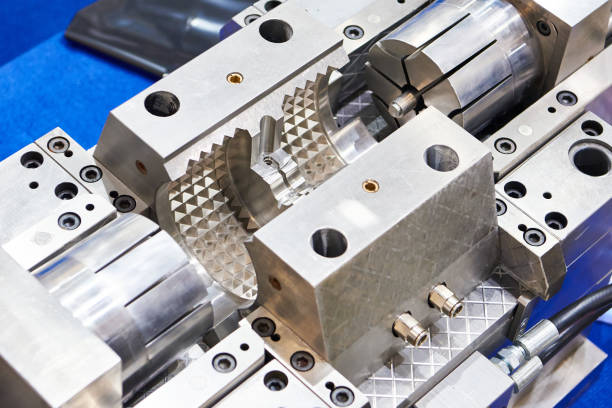

Mold Making: Patterns made from materials like wood or metal are created to form molds for the desired components.

Pouring: The molten metal is poured into the prepared molds.

Cooling: The metal cools and solidifies into the shape of the mold.

Shakeout: The castings are removed from the molds.

Degating: Excess material (gates) is removed from the castings.

Heat Treating: Components may undergo heat treatment to improve mechanical properties.

Surface Cleaning: Any residual material or imperfections are cleaned off.

Finishing: Final touches are applied to meet specific dimensions and quality standards

We integrate a 4-section foundry that utilizes advanced technology and stringent quality control procedures to produce a wide range of castings

We manufacture Grey Cast Iron, Ductile Iron, and Non-Ferrous metals, catering to your specific requirements e.g. Ball Mill Parts, Crusher Jaw Plates, Ship Anchors.

Our in-house pattern production unit is equipped to create both simple and complex patterns for accurate casting replication.

Our in-house pattern production unit is equipped to create both simple and complex patterns for accurate casting replication.

We offers a variety of casting materials to meet specific application requirements tailored to different industrial needs. Some commonly used materials include

Our Channel gratings process are typically made from ductile iron or cast iron which involves:

Pattern Creation: We design patterns based on requested specifications.

Mold Preparation: Molds are created using sand casting techniques.

Pouring: Molten ductile iron is poured into molds designed for channel gratings.

Cooling and Shakeout: After cooling, the gratings are removed from the molds.

Finishing: After Molding we perform Final machining to ensure proper dimensions and surface finish

Manhole covers can also be produced using similar methods:

Pattern Design: Patterns are created to match standard sizes.

Mold Making: We prepare Molds using sand or shell molding techniques.

Metal Pouring: Cast iron or ductile iron is poured into molds.

Cooling and Shakeout: Once cooled, we remove covers.

Finishing Touches: according to design specifications the covers may be coated for corrosion resistance.

Our production of hammers involves:

Mold Creation: Molds are designed based on hammer specifications.

Material Selection: High manganese steel or alloy steel is chosen for durability.

Casting Process:

The selected material is melted.

Molten metal is poured into molds.

Cooling and Quality Control: After cooling, hammers undergo rigorous quality checks to ensure no defects exist.

Heat Treatment: Hammers may be heat-treated to enhance hardness (up to 65 HRC) and wear resistance

Jaw plates used in crushers are produced through:

We manufactured Couplings using:

Counterweights for heavy machinery require:

We produce Liners used in various equipment by:

At D9th Enterprise our industrial foundry casting process encompasses a range of sophisticated techniques tailored to produce diverse equipment essential in many industries.

Each type of equipment—whether it be channel gratings, manhole covers, hammers, jaw plates, couplings, counterweights, or liners—requires specific processes tailored to their unique functional demands and material properties.

Understanding these processes allows us to optimize production efficiency while ensuring high-quality outcomes that meet your industry standards.

Chat us on WhatsApp

We are here to help you with any inquiries or projects.